News

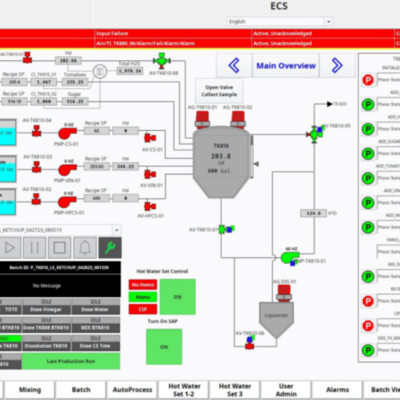

ECS & Ignition Deliver for AmeriQual

Success in many industries is the product of preparation and opportunity. Agility is frequently the lubricant that enables businesses to adapt and win a project or contract. This is especially true in private-label food manufacturing. “The people, processes, and equipment must be able to adapt to ever-changing market demands,” says Wes Blankenberger, Vice President of Operations & Maintenance for AmeriQual Group, LLC, in Evansville, IN (AmeriQual). Brand owners must beat their competition to market and the best way to do that is frequently via a capable private labeling partner. Much like brand owners leverage private label manufacturers, the manufacturing plants themselves leverage partners to assemble existing and new equipment into functional processing systems, often on aggressive timelines.

Similar traits and situations define success inside of the control system integration space. Much like private label manufacturing, clients call upon these firms because of their known ability to deliver in specialized market segments. They’re well-trained and typically gainfully employed by clients where they excel. Rarely are they entirely idle but their mix of professionals at different levels and specialties allows them to apply staff, often on short notice, to applications. Their highly trained teams can tackle projects or parts of projects large and small, often in concert with their teammates or outside firms.

Read More | Posted In: Case Studies, Chemical Industry, Uncategorized

ECS Helps Private Labeler Spring Into Action

When opportunity knocked for a midwestern US private label condiment and sauce manufacturer, their relationship with ECS Solutions, Inc. (ECS) helped them to excel. Success in private-label food manufacturing is often a matter of being able to accept new projects when a chance arrives to expand or acquire new business. Raw capability is a driving factor, but modern manufacturing is not necessarily built on having volumes of idle capacity sitting and waiting for the next project to arrive. These endeavors frequently spawn from a quick flex in schedules, skillful leverage of less-than-optimized equipment, and/or an effective change in technology. Sometimes entirely new operations must rise from nowhere in a seemingly unachievable timeframe, as was the case with ECS’ client.

When this midwestern manufacturer was presented with a chance to land a series of large contracts with a well-known label they quickly pressed all their assets into action to create an entirely new red sauce kitchen. Long lead time items were ordered with less-than-optimal information available. Equipment that could be reused from their local storage cache was inspected, tuned up, and prepared for deployment. Their existing relationships with local contractors allowed them to begin infrastructure preparation immediately and quickly move into detailed piping and wiring. Perhaps most importantly, their relationship with ECS allowed them to quickly assess the project and create a framework so that budgets could be established and bids obtained. It was quickly evident that a fully integrated solution from ECS was not only possible but that it would be integral to long-term success because it would allow for as much effective automation as reasonable, thus minimizing the number of new operating staff members to run the system once complete.

Read More | Posted In: Case Studies, Food Industry

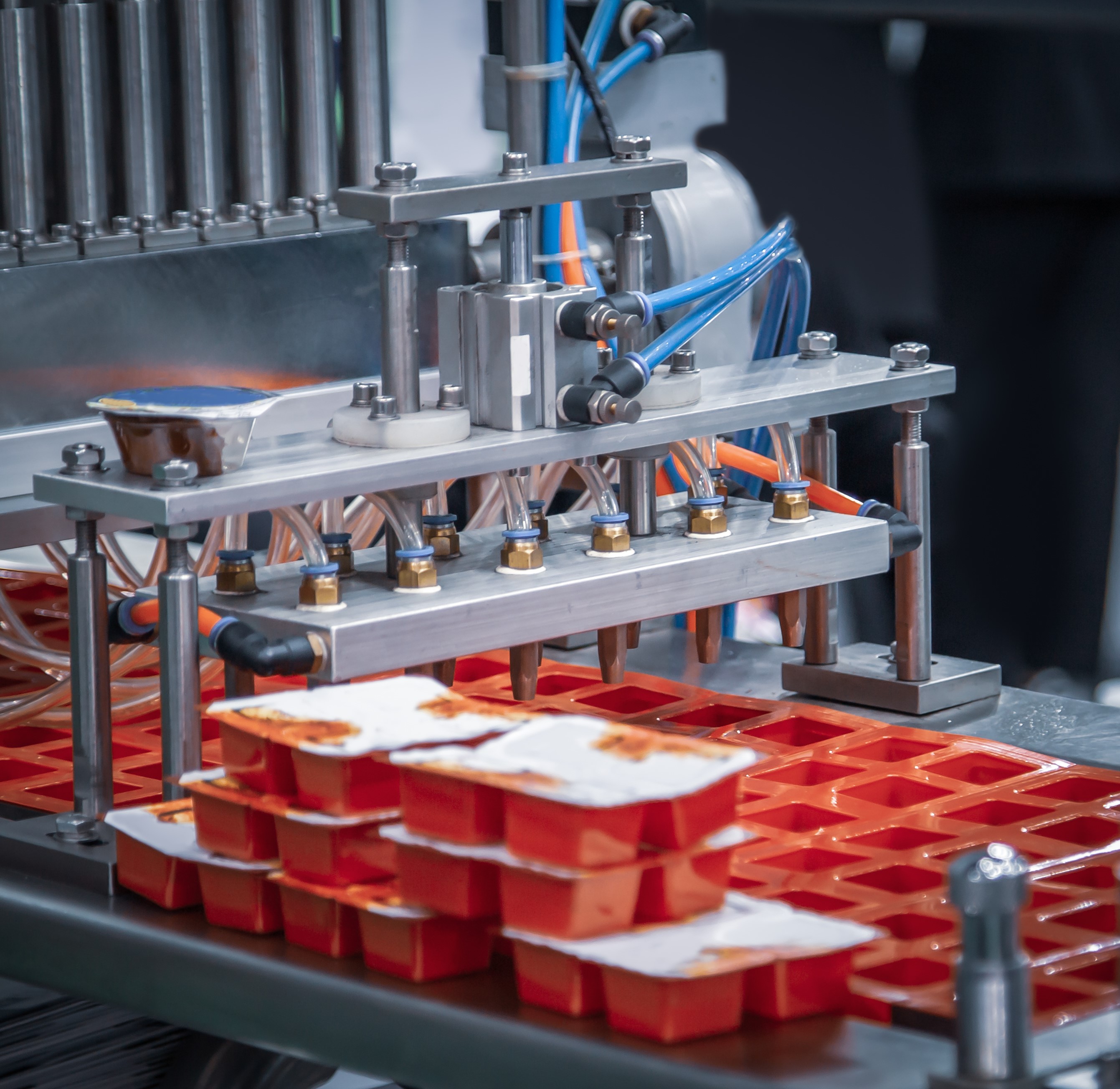

Systems Integrator Extends Packaging OEM’s Reach

Modern packaging plants want tightly integrated line solutions that run their array of products with fewer operating personnel and the easiest possible means for equipment maintenance. Buyers increasingly purchase large-scale packaging solutions from a single vendor with the expertise to deliver these applications. This presents challenges to equipment OEMs, many of whom offer a few niche or high-level equipment with a menagerie of complimentary machines. Many project suppliers are chosen based on their proven ability to handle a specific, complex operation around which the line is anchored, and the additional machines become part of the overall project by default.

It is generally not feasible for focused machine OEMs to also provide the broad-reach solutions required to fully integrate these complex lines. The breadth of staff required to achieve the expertise for detailed machine control along with the adjacent line operations and IT connections would be unbearably expensive for most machine builders. This is especially true because fully integrated options are not part of every option, so OEMs end up with some of their highest-end staff idle on many of the simpler applications that they tackle. These extended solutions frequently come via a dedicated line systems integrator. ECS Solutions (ECS) is a systems integrator that has delivered a huge variety of manufacturing solutions for more than 45 years including highly integrated packaging lines.

Read More | Posted In: Case Studies, Food Industry, Inductive Automation

Embracing the Connections of Automation Projects

The ECS Solutions (ECS) team works on all manner of automation projects, from small to large and from very simple to highly complex. Many of these projects have a major impact on the success of their clients but few are more satisfying than when a project’s results are a dramatic streamlining of plant operations tied in seamlessly with new or upgraded automation.

The most effective manufacturing companies enjoy a harmonious tie-in between the automation that exists, regardless of the level or magnitude, and the other systems that complete the plant operations. Standardized procedures, reduced waste & increased quality, compliance with contracts and regulations, and better employee contribution are all hallmarks of the best manufacturers, and all lead to increased profits.

Read More | Posted In: Case Studies, Food Industry, SCADA

Case Study: Methodical Approach to a Systems Upgrade

ECS Solutions, Inc. (ECS) recently helped a client with an upgrade by leveraging ECS’ methodical approach to system solutions. Their client has three very similar processing areas known as casting pits. Each was controlled by an independent GE 9030 PLC system, each with a main, and each controlled by a local BLUE Open Studio HMI from ProFace America.

The 9030 PLCs that were installed were robust and accurate for these areas when originally installed. Over a long period of time, the systems were maintained and augmented by several personnel from both inside and outside the organization. The result, as is often the case in legacy automation systems, is system drawings that are littered with hand comments and sketches on paper drawings. These systems also feature code that works…. until it doesn’t due to getting lost in a discarded section of logic that was thought to be disabled but was never removed. These situations are often referred to as “ghosts” or “gremlins” in the code and they can be difficult to troubleshoot. Frequently, the solution is to reboot entire systems to exit from the offending area.

Read More | Posted In: Case Studies, Metals Industry, PLCs

Case Study: Brewhouse Automation and Functional Upgrade

ECS Solutions was contracted to replace a control system that was becoming obsolete at a brewery in Florida. The Venezuelan-based parent company, for which ECS Solutions employees had already completed multiple projects, was concerned that the automation hardware could go bad and be difficult to replace, leading to a shutdown of the plant. The customer’s production was at risk since the hardware in the system, which incorporated old Siemens PLC, Siemens I/O (input and output), and Siemen’s software, was no longer supported or available.

ECS Solutions has worked at several of the company’s breweries in South America and had demonstrated the functionality of the ISA88 standard, which allows expansion from producing a few items to many and enables changes to be handled by brewmasters in a modular way without reprogramming the control system. The company wanted the brewmaster to be able to create recipes independent of the code in the PLC, so providing the functionality obtained with the ISA88 standard became an important goal. The company wanted the best practices, now working in the facilities in South America, to be introduced into the Florida plant. (more…)

Read More | Posted In: Beverage Industry, Blogs

Case Study: Integrating PlantPAx into an Existing Process Cell for a Pharmaceutical Company

A major pharmaceutical company was in the process of commissioning a control system for a new process cell and asked ECS to provide site support to complete the commissioning and qualification.

The control system supplier had taken a simplistic approach to keep costs down. A single controller with multiple Panelviews provided the heart of the control system that also interfaced with some OEM skids. The control hardware consisted of a quality Rockwell ControlLogix controller with multiple Panelviews. The controller code was all custom with little use of off-the-shelf products and was an assortment of custom blocks of code tied together, providing minimal functionality.

Little to no thought had been put into the operator and how they would run the system to create quality product. Standard operating procedures had not yet been developed. Producing a quality product was dependent upon the operator selecting the correct sequence of functions from operator stations at multiple vessels. This approach exposed the company to a great deal of risk in producing a quality product and controlling the rate of production.

Read More | Posted In: Case Studies, FactoryTalk Batch

Case Study: An Expansion of a Water Treatment Plant

A municipal utility asked ECS Solutions to design and construct an expansion to one of their Water Treatment Plants. It was proposed to expand an existing facility from ten million gallons per day (MGD) to a total treatment capacity of 30 MGD and upon completion of the expansion, an existing 18 MGD plant was to be shut down.

Earlier, ECS had provided the configuration and start-up support for the SCADA system used to operate the plant and had installed the existing SCADA and control system at both the plant to be expanded, and the one ultimately to be shut down. The proposal provided by ECS Solutions for the expansion covered the control and/or monitoring of:

- Four existing and four new aerators.

- Existing and new primary and secondary settling basins.

- Existing sludge and reclaim equipment.

- All existing and eight new filters.

- Existing and new high service pumps.

- New chemical feed equipment for lime, sodium hypochlorite, fluoride, and polyphosphate.

Read More | Posted In: Case Studies, SCADA

Case Study: FactoryTalk Batch Integration into a Control System for a Pharmaceutical Company

A large pharmaceutical company was commissioning and testing a new control system that was limited to providing only manual control of Equipment Modules. In some cases, manual control of Phases was available, with these Phases operating as coordination Equipment Modules but not having the infrastructure capable of interacting with a standard sequencing engine. To run a Batch Process the operators were required to manually enter recipe values and capture report information via an HMI, while tracking all activities in the various units. This allowed significant opportunities for operator errors (errors in setting parameters, errors in running the Equipment Modules in the correct sequence, or, in some cases, the physical inability to run multiple Equipment Modules at the same time).

ECS Solutions recommended and subsequently undertook the addition of a sequencing engine that not only stores the recipes (which contained the order in which the phases should be executed) but also stores all pertinent Parameter Values. With this modification, the operator is required simply to select a recipe together with all the equipment needed to run the batch. The batch engine is responsible for coordinating all the activities, including the parameter value transfer and Report information capture. The system also has the capability to prompt the operator regarding those tasks that require operator interaction. The installation of the addition did not interfere with any existing activities and all the existent code and functionality was preserved, with no changes being required.

Read More | Posted In: Case Studies, FactoryTalk Batch, Life Science Industry

Case Study: An Upgrade to Ignition Sepasoft “Perspective” OEE & Downtime Module

A global consumer goods manufacturer hired ECS Solutions to evaluate and install an upgrade of an Ignition Application from Version 7.9 to Version 8.1. Version 7.9 was originally installed by ECS Solutions. The overall objective for the company was to have a web-based client application that was independent of Java and based on HTML5. The upgrade included a reconfiguration of the MES software to improve its effectiveness.

The previous Ignition “Vision”-based Application did provide the functionality to monitor Equipment Downtime and Overall Equipment Effectiveness (OEE), but the use of Java within the Ignition modules conflicted with other applications at the site and made it difficult to access throughout the organization. Migration to the web-based Perspective Platform allowed ECS to significantly lighten the application and to focus on the most important data. The new version of the Sepasoft OEE module also made it possible to simplify how the workstream was modeled within the Sepasoft Production module. The company required this application be designed to work with both PCs and iPads.

Read More | Posted In: Consumer Goods