News

Improve Cooking Quality Utilizing the Lethality Factor Principles

Cooking (thermal processing) is critically important for controlling the levels of foodborne pathogens in products. Cooking is an effective process for eliminating, or at least reducing to acceptable levels, any pathogenic bacteria that may be present in the products. Today thermal processing is applied to literally hundreds of types of manufacturing processes from hams to jerky and many other industries.

There is a wide variety of processes, schedules, and equipment used in cooking areas. Furthermore, the products have unique compositions, e.g., fat and moisture content, ingredients, and other characteristics that can create different responses to the thermal processing technology used. It becomes important to appreciate how different processing systems and schedules affect product lethality, i.e., the capacity to cause death or serious harm to the non-desirable.

Cooking or thermally processing typically involves heating the product to a pre-determined temperature and holding the temperature for a minimum length of time. How variable is this process? The temperature varies with different equipment and can impact the desired result. The choice of “starting time” is another variable. It may be taken to be when the desired temperature is reached or is measured from when heating begins. Hence there is a significant variation in the measured temperature-time profiles in order to destroy the pathogens. For example, there is a dramatic decrease in the time required to destroy both salmonella and listeria in ham, beef and turkey, at temperatures above 131°F relative to temperatures below 131°F.

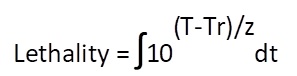

The mathematical integration of temperature-time profiles is a measure of the extent of heat exposure of the product. This offers a practical approach to determine the lethality factor for a product. Early efforts to use this approach were limited by the inability of programs such as Excel to carry out the integration. Today’s processors incorporate into the control systems for automated processes have underutilized functionality that can easily be used to integrate the data collected as temperature-time profiles. The incorporation of a lethality equipment module, which uses existing controller instructions to complete the integration of the temperature-time profiles, provides a reliable indicator of the amount of heat exposure of the product.

There are several benefits to adopting a lethality module, particularly since improved product quality and quantity is realized, together with the overall reduction in production costs. Other benefits include reduction of cooking time, repeatability of cooking exposure, energy conservation, the elimination of potential human error since no manual data collection is required, and the automated system can proceed without operator intervention once the required lethality exposure has been met. ECS believes that integration of temperature-time profiles can provide a reliable and convenient tool to ensure compliance with industry standards, and, at the same time optimize product quality.

Posted In: Bakery Industry, Batch Boosters, Food Industry, White Papers