News

Case Study: Product Life Expiration Automation

All the production processes carried out in a particular process cell within a large, national food manufacturing company, must adhere to certain time guidelines, a consequence of the relatively short shelf lives of some of the ingredients.

A batch process is monitored manually with operators following the batch through the stages and vessels involved. The production times are recorded on paper by an operator and tracked to ensure the time guidelines are maintained. The batching process at the various stages should not exceed the specified maximum time. Failure to meet these criteria will result in the product being scrapped. It is both difficult and cumbersome to reliably record and track the batch process creating the possibility for errors to occur. The food company sought a more reliable way to track the product life of the batches as well as providing information for quality control and regulatory purposes. The company requested ECS Solutions evaluate the possible automation of the time guidelines. ECS proposed a solution for the automation but limited it to the guidelines on the “in process batching” vessels. Automation of other vessels and guidelines could be carried out, but due to information available and a desire to minimize the scope, the project was limited to the in-process batching vessels.

To track each “in process” unit (vessel) in the process cell, including pre-emulsion (PE) kettles, batch, and surge kettles, ECS focused on the following four times:

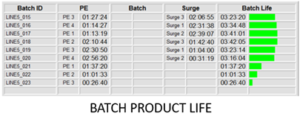

- Batch Product Life, i.e., the time a specific batch has been in production is accumulated over multiple units. The timer is activated to record the batch ID, when the first ingredient of the batch is delivered into a unit and continues from the PE to the batch and surge tanks, ending when it is transferred out to the filler.

- Unit Product Life., the time that the batch or ingredient has been in the particular kettle. The timer begins when the product is delivered into the kettle and continues until it is transferred out.

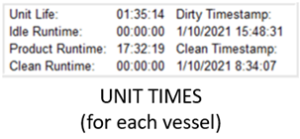

- Unit Idle Time i.e., the time that the unit remains empty between ingredients or batches once the kettle has been put into production with the product (idle time between batches or ingredient refills).

- Unit Clean Time., monitoring the time the kettle has been clean and idle. A dirty timestamp is captured and displayed at the time a unit becomes unclean from the addition of an ingredient or a batch. A clean timestamp is captured and displayed once a CIP has been completed.

ECS developed and applied the timers to multiple vessels and provided the necessary programming and configuration modifications to the ControlLogix controllers and the HMI’s to track times as the batch is processed. Timer logic was added to the appropriate unit and equipment module logic within the controller, eliminating any need to change the FactoryTalk Batch recipes or area model. A dashboard was set up for the operators to see the times to show the Batch Product Life and an individual virtual gauge was generated for each vessel on the HMI to show the unit times.

After thorough testing in a simulated environment, ECS provided site services to install and commission all the changes.

The automation modifications reduced variability in the manual procedure, reduced errors, and provided a visualization tool to the operators.

In the future, the company wants to utilize these timers to eliminate variability in the procedure leading to a problem with a given batch or ingredient. A flag will be included to interrupt the process when such a non-compliance occurs, allowing a quality control decision point or automatically sending the product to a waste tank.

With a similar project being implemented concurrently, ECS is providing a type of scheduler. The HMI visualization will show:

- when batches are running

- when CIPs are in progress

- when equipment is idle and could be put into production or be cleaned by a CIP process

ECS considered this “adding functionality,” representing another piece of the production throughput or OBE (overall batching effectiveness).

Posted In: Case Studies, Food Industry, News