News

Chemical Manufacturer Upgrades Critical Systems

A midwestern US chemical plant plays an integral part of the worldwide supply of stock for animal feed, refined human vegetable oils, and various other products. This family-owned operation has been a powerhouse in soybean processing, specifically, for more than half a century. As such, their processing areas for that product specifically are considered the epitome of “critical” and run year-round with only a single annual shutdown to handle most large-scale maintenance and upgrade projects.

As this plant looked to install the first ever automation to their critical extraction and shared cooler areas, they knew that this would be a large-scale project that would encompass a multitude of equipment and trades and that the installation would span several years. This project would require partners who could handle the technical scope as well as the extended and complex project management.

Read More | Posted In: Case Studies, Chemical Industry

DVR Module for Troubleshooting and Continuous Improvement

Effective mass production manufacturing operations involve both monitoring of production processes and continual improvement. ECS Solutions, Inc (ECS) has developed an innovative, powerful tool to help their clients develop peace of mind that their products are being manufactured accurately and efficiently while providing a platform to easily improve future interactions. The Process DVR tool satisfies the modern expectation that anything that can be observed visually should be recorded and easily viewed later. When used effectively, the result is truly optimized production control where the best-trained operators deliver accurate results with the least possible waste.

Data Historian capabilities have been built into many vendors’ SCADA systems for a long time. Astute process engineers can call up trending information that illustrates the states and conditions within an automated system, the multitude of lines crisscrossing an HMI terminal in a way their trained eyes can discern. This is an excellent tool by itself, provided that an operation has personnel who are trained to read and interpret the cryptic information that is returned from a standalone Historian. ECS believed that this was conceptually sound but that a more manageable solution would help to bring wider benefits to their processing clients.

Read More | Posted In: Bakery Industry, Beverage Industry, Chemical Industry, Clean in Place, Digitalization, Distilleries, Food Industry, Inductive Automation, Life Science Industry, SCADA

How to Identify, Quantify, and Mitigate Risk in Industrial Operations

A key responsibility of executives and managers in manufacturing is that of risk management. This refers to the obvious risk of physical operations and staff protection, but it also includes quite a bit more: risk to contracts, availability of brands of the direct employer and those of other clients, reputation(s), regulatory, and risk to public safety and health are all increasing concerns with the operating level of a senior executive or manager.

Risk identification is a critical first step; without which, corrective actions cannot be undertaken or could possibly be misguided. Because risks evolve constantly, it is rare that they can be spelled out in a succinct and comprehensive volume. One obvious solution is to install the correct staff in the tiers immediately below the executives but that often raises questions about the specific qualifications of these employees, their tenure and familiarity with every facet of their role within that organization, and whether an overarching net has been cast to identify and compartmentalize relative risks. Further concerns arise around whether an internal team is free of groupthink and whether they possess the proper experience, qualifications, and motivations. (more…)

Read More | Posted In: Bakery Industry, Beverage Industry, Chemical Industry, Food Industry, Life Science Industry, Metals Industry

The Process Functional Ecosystem

Companies that operate in multi-step, multi-ingredient batch processing operations employ a combination of complex procedures, business and operational systems, and communications. The range of tools and machinery used to process a potentially vast array of ingredients and process steps are what it takes to make processors successful. Entire working cultures emerge from these operations that foster a focus and achieve positive outcomes.

The more specialized the market and operation, the lower number of people who operate within that domain. This doesn’t always allow for regular interaction with a broad spectrum of manufacturing peers, which can leave individuals and organizations feeling they are so unique that they are relatively isolated. They frequently feel little confidence that people outside their close-knit internal group can effectively understand, let alone support them. The possibility exists that they are rare, but they are not entirely unique and there are outside firms that are also closely aligned and, in fact, true peers as well.

ECS Solutions (ECS) operates upon this landscape. They have established a collective corporate consciousness that is aligned with the DNA of their core clients: batch processors. ECS is immersed in the behaviors and characteristics of these clients, and it is reflected in nearly every aspect of their operation. (more…)

Read More | Posted In: Bakery Industry, Beverage Industry, Chemical Industry, Food Industry, Metals Industry, News

Dynamic Perspective Objects with Sepasoft’s Batch Module

One of the most exciting things about Sepasoft’s Batch and Procedure module is that it enables tight integration between the process cell (as it is functionally defined) and the graphical interface (how it is presented to the user). By using the various tools in the Ignition toolbox (creative scripting, querying, and binding), it is possible to create dynamic views that represent the ISA-88 objects of a process cell. As the process cell definition changes (new units, new phases, etc) these dynamic objects automatically update as needed. This allows for less development time, a consistent user experience, and a lower maintenance control system. (more…)

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Food Industry, Inductive Automation, Life Science Industry, Metals Industry, News

Surviving the Great Resignation

A rapidly decreasing number of technical personnel are available who can install and maintain the higher-end equipment used in manufacturing today. “The great resignation and/or retirement” movement, along with changes associated with the recent pandemic landscape, has sent many highly qualified workers to the exits in search of new and often altogether different opportunities. The stage has been set for decades with the wave of baby boomer retirements churning towards manufacturers. Parallel to this has been the increased reliance on high-tech manufacturing machines and processes. These two situations pair well with the idea of future-proofing low-to-mid complexity manufacturing but, in an interesting juxtaposition, amplify the core problem. (more…)

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Food Industry, Life Science Industry, Metals Industry

Batch Forensics: Additional Report Parameters Enhance Process Performance

Understanding your process performance starts with having unambiguous data that is contextualized. This data provides information that quantifies and qualifies the different aspects that provide insight into the overall system performance. This data ends up in a repository and gets analyzed to produce actionable information and these reports may look at different aspects of the activities required to make products or to clean the equipment. By looking at the process from the ISA 88 and ISA95 point of view, we are able to provide additional context to the information for which the basic activities are reporting.

Understanding your process performance starts with having unambiguous data that is contextualized. This data provides information that quantifies and qualifies the different aspects that provide insight into the overall system performance. This data ends up in a repository and gets analyzed to produce actionable information and these reports may look at different aspects of the activities required to make products or to clean the equipment. By looking at the process from the ISA 88 and ISA95 point of view, we are able to provide additional context to the information for which the basic activities are reporting.

Additional information may be added to provide more insight into the activities related to:

- Quality – (amounts, tolerances, durations, temperatures, lethality, etc.)

- Cost- (materials, energy, personnel, equipment, etc.)

- Material information – (lot ID, material properties, storage locations, etc.)

- Personnel – (who is performing tasks, signoffs, etc.)

- Energy – (transport, heat/cool, mix, etc.)

- Equipment – (raw material source, equipment utilization, portable equipment information.)

– as well as other aspects that can be used to make informed decisions. (more…)

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Food Industry, Life Science Industry, Metals

Batch Forensics by ECS Solutions

The term forensics refers to the application of scientific knowledge to problems, especially scientific analysis, and data analysis of physical evidence. In a plant environment, data and scientific analysis can be the key to discovering opportunities to improve the automation solution that exists, forensic tools can be implemented in all phases of the life cycle of a system, but ideally, they should be considered during the design phase.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry, Metals

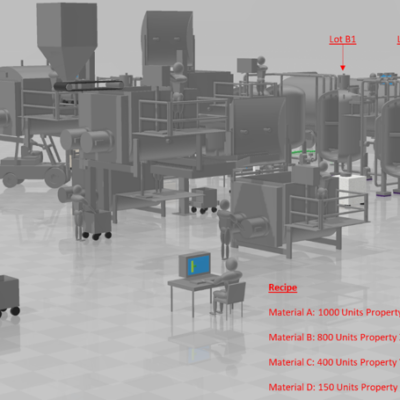

Dosing Materials Based On Their Properties

Improving Product Quality

Often the quantities of materials required to manufacture a product are specified by weight or by volume. Recipes and procedures are created to specify the activities that need to be performed and the number of materials required.

The Setpoints for these quantities are set in the recipes based on the materials that are being used, if the material properties change significantly then these recipe quantities need to be updated once the new materials enter the production stream. This often requires tracking the material consumptions and updating the recipes at the appropriate time. i.e. late at night on Saturday once the new material is introduced to the production environment.

These new formula quantities are calculated after a lab analysis is performed of each Lot sample. The timing to introduce these new recipe parameter values can be critical to the Quality and the Cost of the product.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers

Documenting Your Manufacturing Ecosystem

Understanding your manufacturing ecosystem is one thing, but documenting it is just as important. Having extensive documentation of the manufacturing ecosystem, helps those who aren’t involved in daily, plant-floor operations make informed decisions. Your manufacturing ecosystem is the system you use for making your product(s), and fully documenting and understanding this ecosystem will help the decision-making process of your organization.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry