News

Dosing Materials Based On Their Properties

Improving Product Quality

Often the quantities of materials required to manufacture a product are specified by weight or by volume. Recipes and procedures are created to specify the activities that need to be performed and the number of materials required.

The Setpoints for these quantities are set in the recipes based on the materials that are being used, if the material properties change significantly then these recipe quantities need to be updated once the new materials enter the production stream. This often requires tracking the material consumptions and updating the recipes at the appropriate time. i.e. late at night on Saturday once the new material is introduced to the production environment.

These new formula quantities are calculated after a lab analysis is performed of each Lot sample. The timing to introduce these new recipe parameter values can be critical to the Quality and the Cost of the product.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers

Documenting Your Manufacturing Ecosystem

Understanding your manufacturing ecosystem is one thing, but documenting it is just as important. Having extensive documentation of the manufacturing ecosystem, helps those who aren’t involved in daily, plant-floor operations make informed decisions. Your manufacturing ecosystem is the system you use for making your product(s), and fully documenting and understanding this ecosystem will help the decision-making process of your organization.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry

Material Dosing Geneology

The Food industry uses batch manufacturing extensively and therefore requires traceability for material ingredients, i.e. the ability to follow the movement of a food product and its’ constituents all through the production process.

This capability not only largely prevents unsafe foods from reaching the consumer but also improves product quality and efficiency in the event of a recall.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers

The Benefits of Off-The-Shelf SOP Management Software

Being able to keep track of every step and every bit of data is a major necessity for every organization. An off-the-shelf standard operating procedure software is one way to implement new processes and keep track of business operating standards.

Tracking manual operations in discrete, batch, and continuous manufacturing processes can greatly benefit from off-the-shelf products. Clearly specifying your procedures, enforcing their execution, and capturing pertinent data are all major benefits that can be quickly and easily be obtained by implementing off-the-shelf, procedure management software.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry

Bardstown Bourbon Company Case Study

The Challenge

Bardstown Bourbon Company (BBC) is a Bourbon Distillery located in Bardstown Kentucky. Utilizing two mash cookers, 32 fermenters, two distillation stills, and nine cistern holding tanks, BBC produces a wide variety of high-quality whiskeys and bourbons. (more…)

Read More | Posted In: Case Studies, Distilleries, Inductive Automation

Securing your Intellectual Property

Production procedures and formula values property

How secure is the intellectual property of your products?

Many degrees of automation exist in manufacturing plants, but they all have a common requirement– specifying the activities and the order in which they need to occur as well as the key setpoints such as materials, amounts, tolerances, temperatures, durations, etc.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, MES, Metals, White Papers

The Importance of Material Tracing

Traceability on a processing or production line is incredibly important, especially when it comes to food products, where having the ability to track every ingredient down to the source is crucial to the health and safety of the consumers.

As parts of the country begin to move out of COVID-19 shutdowns, we have been hearing about “contact tracing” as a tool for containing a secondary spread of the disease. Material, lot tracing, or traceability has been part of producing safe food products for a long time. The concepts behind contact tracing and material tracing are similar.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry, Metals

Materials and Lot ID Traceability

In the event of a recall can you find everything you need to know in an expeditious way.

As per Wikipedia, “Traceability” is the capability to trace something. In some cases, it is interpreted as the ability to verify the history, location, or application of an item by means of documented recorded identification.

In the process industry, we are required to know the whereabouts of the raw and intermediate materials as well as the finished products. This is paramount since recalls can be impactful to the safety of the consumer as well as financially to the producers.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers

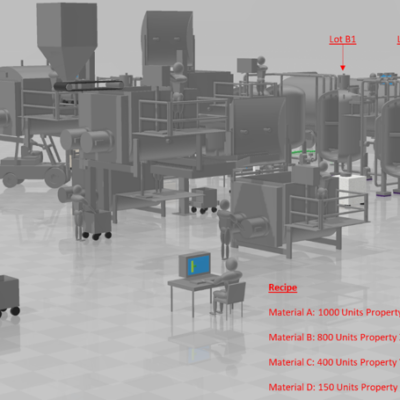

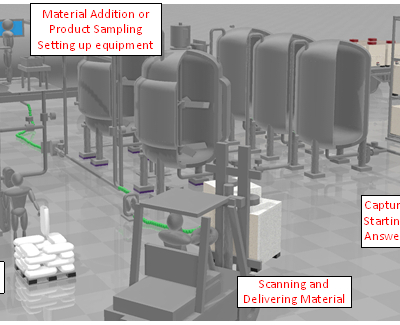

Automated Procedures for Manual Processes

Process customers do not need to automate their equipment to start taking advantage of some of the important benefits that off-the-shelf automation products possess. Processes that are typically operated manually can benefit from automating their procedural execution, meaning that the activities that operator typically perform by following printed Standard Operating Procedures can be Specified, Enforced, and Verified in electronic form.

Off-the-shelf products allow us to Specify recipes that can span multiple unit procedures. These can be enforced by prompting the operator or operators of the different areas to perform the required manual activities in the order specified, information normally captured on a sheet of paper or batch log can be annotated and journaled electronically and then this information can be instantly used to make decisions on the active recipe (i.e. adjust the amount of material to be added based on a sample analysis).

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, Metals, White Papers

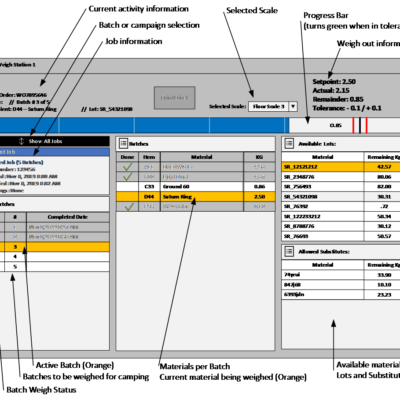

Weighing In Dispensing System

Manual weighing and dispensing tracked electronically.

Automating the dosing of Minor and Micro ingredients is often cost-prohibitive. These tasks are often performed manually by operators that weigh the required materials then dose them to the required destination at the appropriate time. These procedures are typically guided by Paper Standard Operating Procedures (SOP’s) that are used to track progress and capture required information manually.

These activities can be conducive to errors that are captured downstream after additional value has been added to the raw materials, some of these errors cause batches to be reprocessed or rejected.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers