News

ECS Proud to Support T.R.E.K.

ECS Solutions is always looking to support programs that encourage young people to explore the engineering and manufacturing industries. A strong workforce starts with exposure to these important fields long before college. This summer we are proud to be a sponsor for the T.R.E.K. Summer Experience.

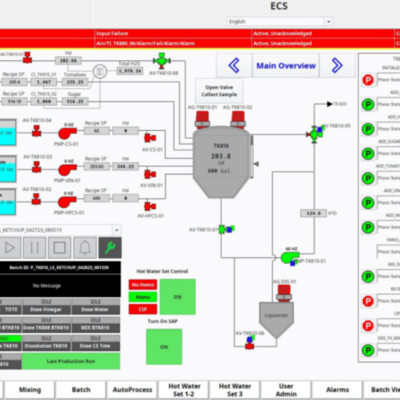

ECS & Ignition Deliver for AmeriQual

Success in many industries is the product of preparation and opportunity. Agility is frequently the lubricant that enables businesses to adapt and win a project or contract. This is especially true in private-label food manufacturing. “The people, processes, and equipment must be able to adapt to ever-changing market demands,” says Wes Blankenberger, Vice President of Operations & Maintenance for AmeriQual Group, LLC, in Evansville, IN (AmeriQual). Brand owners must beat their competition to market and the best way to do that is frequently via a capable private labeling partner. Much like brand owners leverage private label manufacturers, the manufacturing plants themselves leverage partners to assemble existing and new equipment into functional processing systems, often on aggressive timelines.

Similar traits and situations define success inside of the control system integration space. Much like private label manufacturing, clients call upon these firms because of their known ability to deliver in specialized market segments. They’re well-trained and typically gainfully employed by clients where they excel. Rarely are they entirely idle but their mix of professionals at different levels and specialties allows them to apply staff, often on short notice, to applications. Their highly trained teams can tackle projects or parts of projects large and small, often in concert with their teammates or outside firms.

Read More | Posted In: Case Studies, Chemical Industry, Uncategorized

High Performance Rubber Batching by ECS

ECS Solutions, Inc (ECS) recently used its extensive batch experience and dynamic company structure to help a major Southeast US rubber manufacturer realize and achieve project success. The end client had an existing semi-automated batch and mixing operation and had recently commissioned a project to duplicate this line’s operation with a new mix room, ingredient systems, and rubber mixer. They employed a powerhouse electrical contractor to connect all the new equipment and make it operate as a single system and this was largely successful. However, as the project moved through its lifecycle, the team realized that sophisticated batch operations would require specialized talents that were missing from the initial project team.

A quick web search for batch expertise within the region quickly pointed to ECS. It’s rare that ECS assets are idle, waiting for project work to arrive, and that was true in this case. Fortunately, the electrical contractor was a proven operator who had the situation in check with respect to major control equipment, general electrical planning, and installation, so ECS was able to apply only batch-specific resources and a slim project management umbrella. The ECS team quickly mobilized and took control of the batch portion of the project.

Read More | Posted In: Case Studies, Chemical Industry

Native Spanish Speakers Drive Results at ECS

ECS Solutions (ECS) continually evolves to respond to the needs of our clients. In many cases, this is evident in the form of new services or specialized training and certifications to address changing technology. Another area where we have placed considerable emphasis over the last decade is diversity within the ranks of the ECS team. Specifically, we have placed marked effort into growing the number of our native Spanish-speaking teammates.

According to the US Department of Labor, the overall composition of Hispanic workers grew from 8.5% in 1990 to 18% in 2020. They project that this will be over 21% of the overall workforce by 2030. In 2020 Hispanic workers already made up more than 25% of the total workforce in six states including key agricultural locations like California, Arizona, Texas, and Florida. The Bureau of Labor Statistics states that the number of Hispanic workers in management jobs more than doubled to over 10% today from just over 5% in 2000.

ECS is thrilled to be named “One of Indiana’s Best Places to Work” again!

ECS is thrilled to be named “One of Indiana’s Best Places to Work” for the fourth year in a row!

A multitude of industries from across the state are represented on the 2023 Best Places to Work in Indiana list – with a total of 125 Hoosier businesses recognized, including nearly 40 newcomers from last year. This marks the 18th edition of the Indiana Chamber of Commerce initiative.

PlantPAx Objects for Chemical Processor

ECS Solutions, Inc. (ECS) recently executed an increasingly rare upgrade for a midwestern chemical processor. The application was rare in that the facility and its controls were neither a brand new, greenfield design nor an upgrade from existing, controller-based automation. This grain processor utilizes volatile hexane in their oil extraction operations so the facility has classified locations throughout. Thus, the legacy control system leveraged pneumatic integration, and hard-wired, and hard-plumbed control loops. That system served them admirably for years and was left in place until this was replaced with a modern electrical system at the direction of ECS.

To facilitate a clean project that could be adopted easily by seasoned operators, ECS built the automation using Rockwell Automation ControlLogix hardware and PlantPAx objects for the code. The robust library of process objects made the code generation very straightforward, and the controller code coupled seamlessly to the Rockwell FactoryTalk View SE SCADA. ECS’ high-performance HMI design focused on a simple, flatter overall concept that leveraged color and animation effectively to drive efficient user interaction. Information from code easily passes to the newly deployed FT Historian system, sharing the same information to the long-term storage.

Read More | Posted In: Case Studies, Chemical Industry

Using Ignition Scripting Libraries

Volumes have been written about the proper use of tools within a software application and how to create projects for maximum efficiency in both development and execution. Senior programmers and leaders of development teams strive to write and deploy robust solutions that are simple, efficient, easy to debug, and easy to adapt in the future.

Ignition is a multi-faceted tool that continues to revolutionize industrial applications. The package includes a powerful scripting tool that has undergone significant upgrades from versions 7 and before and has existed in its current form since version 8. When combined with the software’s other capabilities and using a disciplined approach to the application of all the tools, Ignition can give you efficient and optimized solutions that can solve most SCADA and business integration challenges.

Read More | Posted In: Blogs, Inductive Automation

Ignition Perspective® Module

Human-machine interface (HMI) vendors have been promising a utopia based around web-based technologies for over two decades. The prospect of simply providing a web address to anyone within an organization that leads to a fast-loading, full-power supervisory control and data acquisition (SCADA) system has been on most factories’ wish list for a long time. After all, internet page tools and functionality have far outpaced advancements in SCADA software over the same time. The advancements seem to leap forward every time someone reloads a page, with new widgets and tools available almost daily. When coupled with hardware developments like high contrast screens; enhanced touchscreen operations; and capabilities like Bluetooth, accelerometers, geolocation, and more; a flexible, web-based option has been coveted.

What many casual users fail to understand about HMI solutions is exactly how tightly the software is connected to the factory floor controllers. This connection via high-security networks, VPNs, and masks, can be tricky to navigate, particularly when the architecture is intentionally complex to provide security for the systems. Further, most people don’t realize the architectural complexity of software that link to sometimes multiple databases and remote data sources, where gigabits of proprietary information streams into and out of the SCADA application. It has been the responsibility of the integrators of these solutions to protect would-be users from themselves in a lot of applications. Poorly developed programs could create vulnerabilities to the operation of equipment, expose floor workers to potential risk, and possibly allow trade secrets to escape into cyberspace.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Inductive Automation, Metals Industry, SCADA

ECS Helps Private Labeler Spring Into Action

When opportunity knocked for a midwestern US private label condiment and sauce manufacturer, their relationship with ECS Solutions, Inc. (ECS) helped them to excel. Success in private-label food manufacturing is often a matter of being able to accept new projects when a chance arrives to expand or acquire new business. Raw capability is a driving factor, but modern manufacturing is not necessarily built on having volumes of idle capacity sitting and waiting for the next project to arrive. These endeavors frequently spawn from a quick flex in schedules, skillful leverage of less-than-optimized equipment, and/or an effective change in technology. Sometimes entirely new operations must rise from nowhere in a seemingly unachievable timeframe, as was the case with ECS’ client.

When this midwestern manufacturer was presented with a chance to land a series of large contracts with a well-known label they quickly pressed all their assets into action to create an entirely new red sauce kitchen. Long lead time items were ordered with less-than-optimal information available. Equipment that could be reused from their local storage cache was inspected, tuned up, and prepared for deployment. Their existing relationships with local contractors allowed them to begin infrastructure preparation immediately and quickly move into detailed piping and wiring. Perhaps most importantly, their relationship with ECS allowed them to quickly assess the project and create a framework so that budgets could be established and bids obtained. It was quickly evident that a fully integrated solution from ECS was not only possible but that it would be integral to long-term success because it would allow for as much effective automation as reasonable, thus minimizing the number of new operating staff members to run the system once complete.

Read More | Posted In: Case Studies, Food Industry

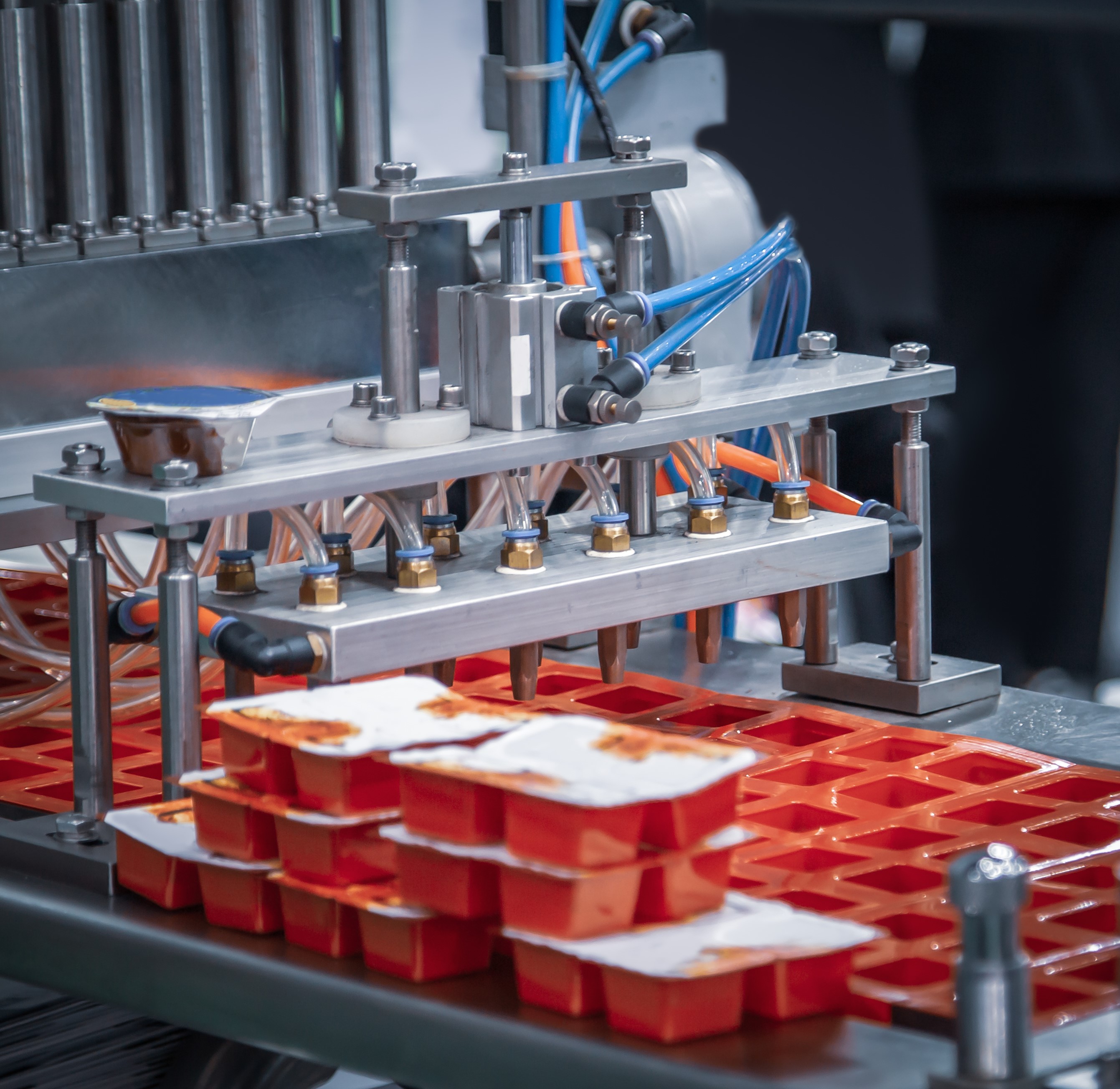

Systems Integrator Extends Packaging OEM’s Reach

Modern packaging plants want tightly integrated line solutions that run their array of products with fewer operating personnel and the easiest possible means for equipment maintenance. Buyers increasingly purchase large-scale packaging solutions from a single vendor with the expertise to deliver these applications. This presents challenges to equipment OEMs, many of whom offer a few niche or high-level equipment with a menagerie of complimentary machines. Many project suppliers are chosen based on their proven ability to handle a specific, complex operation around which the line is anchored, and the additional machines become part of the overall project by default.

It is generally not feasible for focused machine OEMs to also provide the broad-reach solutions required to fully integrate these complex lines. The breadth of staff required to achieve the expertise for detailed machine control along with the adjacent line operations and IT connections would be unbearably expensive for most machine builders. This is especially true because fully integrated options are not part of every option, so OEMs end up with some of their highest-end staff idle on many of the simpler applications that they tackle. These extended solutions frequently come via a dedicated line systems integrator. ECS Solutions (ECS) is a systems integrator that has delivered a huge variety of manufacturing solutions for more than 45 years including highly integrated packaging lines.

Read More | Posted In: Case Studies, Food Industry, Inductive Automation