News

The Top Five Benefits of Tuning PID Loops in Process Control Systems

Process control systems are the backbone of efficient and reliable manufacturing operations, ensuring predictability, stability, and optimized performance across various industries. Whether managing the precise control of temperatures, pressures, or flow rates, these systems play a vital role in delivering consistent output, reducing waste, and upholding safety standards. At the heart of many process control systems lies the Proportional-Integral-Derivative (PID) loop—a powerful mechanism that, when properly tuned, can drive significant benefits for manufacturers.

Let’s examine the five key reasons why tuning PID loops is essential for improving your process control systems.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Clean in Place, Consumer Goods, Distilleries, Food Industry, Life Science Industry, Metals, Metals Industry, News

ECS Solutions has acquired the assets of HTI Inc. of Horse Branch, KY

ECS Solutions, Inc. founded in 1977, and dedicated to performance improvement and innovation in batch manufacturing, has acquired the assets of HTI Inc. of Horse Branch, Kentucky. HTI Inc was founded in 1996 with a primary focus on serving Water and Wastewater municipal customers. The company specialized in water and wastewater plant process control design, implementation, and related services. The company was known for its expertise in remote “telemetry” solutions, utilizing multiple communications platforms such as Narrowband radio communications, spread spectrum radio communications, ISP, and Cellular networks. HTI offered PLC-based process controls, SCADA/HMI development, and provided and maintained process measurement and online water quality analytical instrumentation.

“ECS is very excited about this partnership with HTI. We have looked at the Kentucky market as a vibrant, growing industrial area. With HTI’s established local presence, ECS can augment their existing skills with increased capacity and a specialized skillset in batch process automation. Together we can better serve this geography and the Water/Wastewater market.” said Randy Otto, ECS Solutions CEO.

Read More | Posted In: Bakery Industry, Beverage Industry, Chemical Industry, Clean in Place, Consumer Goods, Distilleries, Food Industry, Life Science Industry, Metals Industry, News

DVR Module for Troubleshooting and Continuous Improvement

Effective mass production manufacturing operations involve both monitoring of production processes and continual improvement. ECS Solutions, Inc (ECS) has developed an innovative, powerful tool to help their clients develop peace of mind that their products are being manufactured accurately and efficiently while providing a platform to easily improve future interactions. The Process DVR tool satisfies the modern expectation that anything that can be observed visually should be recorded and easily viewed later. When used effectively, the result is truly optimized production control where the best-trained operators deliver accurate results with the least possible waste.

Data Historian capabilities have been built into many vendors’ SCADA systems for a long time. Astute process engineers can call up trending information that illustrates the states and conditions within an automated system, the multitude of lines crisscrossing an HMI terminal in a way their trained eyes can discern. This is an excellent tool by itself, provided that an operation has personnel who are trained to read and interpret the cryptic information that is returned from a standalone Historian. ECS believed that this was conceptually sound but that a more manageable solution would help to bring wider benefits to their processing clients.

Read More | Posted In: Bakery Industry, Beverage Industry, Chemical Industry, Clean in Place, Digitalization, Distilleries, Food Industry, Inductive Automation, Life Science Industry, SCADA

Large Consumer Goods Case Study

THE CHALLENGE

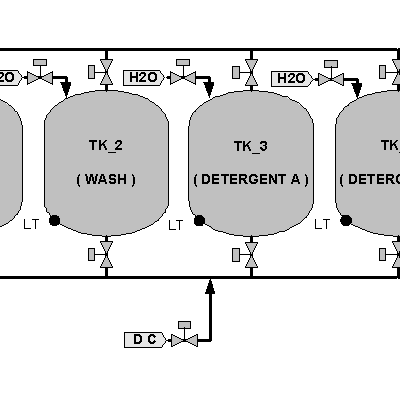

ECS was hired to upgrade and replace a CIP control system in one of the manufacturing areas for a large consumer goods company. The scope of work included a new control enclosure containing an upgrade from a SLC5 controller to a ControlLogix controller. The upgrade also consisted of all IO and connections within the enclosure. Additionally, the company wanted to solve the problem of inefficiencies in its CIP process by implementing FactoryTalk Batch and Batch control within this updated CIP system.

Read More | Posted In: Case Studies, Clean in Place, Consumer Goods

Flexible and Modular CIP and SIP Automation Enables Continuous Improvements

Clean In Place (CIP) and Steam in Place (SIP) constitute critical aspects of the bottom line of a manufacturing process, just as important as the products manufactured with the assets, CIP and SIP play a very important role in the product quality as well as the overall availability of the equipment to manufacture these products. Being able to consistently execute the required cleaning step regardless of the equipment level of automation is paramount, and being able to clearly specify and enforce the steps required are critical regardless of how these tasks are executed. Operators and equipment should seamlessly perform their task to ensure the desired cleaning procedures are executed in an optimum manner.

Read More | Posted In: Batch Boosters, Clean in Place, White Papers