News

Dynamic Perspective Objects with Sepasoft’s Batch Module

One of the most exciting things about Sepasoft’s Batch and Procedure module is that it enables tight integration between the process cell (as it is functionally defined) and the graphical interface (how it is presented to the user). By using the various tools in the Ignition toolbox (creative scripting, querying, and binding), it is possible to create dynamic views that represent the ISA-88 objects of a process cell. As the process cell definition changes (new units, new phases, etc) these dynamic objects automatically update as needed. This allows for less development time, a consistent user experience, and a lower maintenance control system. (more…)

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Food Industry, Inductive Automation, Life Science Industry, Metals Industry, News

Surviving the Great Resignation

A rapidly decreasing number of technical personnel are available who can install and maintain the higher-end equipment used in manufacturing today. “The great resignation and/or retirement” movement, along with changes associated with the recent pandemic landscape, has sent many highly qualified workers to the exits in search of new and often altogether different opportunities. The stage has been set for decades with the wave of baby boomer retirements churning towards manufacturers. Parallel to this has been the increased reliance on high-tech manufacturing machines and processes. These two situations pair well with the idea of future-proofing low-to-mid complexity manufacturing but, in an interesting juxtaposition, amplify the core problem. (more…)

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Food Industry, Life Science Industry, Metals Industry

Case Study: FactoryTalk Batch Integration into a Control System for a Pharmaceutical Company

A large pharmaceutical company was commissioning and testing a new control system that was limited to providing only manual control of Equipment Modules. In some cases, manual control of Phases was available, with these Phases operating as coordination Equipment Modules but not having the infrastructure capable of interacting with a standard sequencing engine. To run a Batch Process the operators were required to manually enter recipe values and capture report information via an HMI, while tracking all activities in the various units. This allowed significant opportunities for operator errors (errors in setting parameters, errors in running the Equipment Modules in the correct sequence, or, in some cases, the physical inability to run multiple Equipment Modules at the same time).

ECS Solutions recommended and subsequently undertook the addition of a sequencing engine that not only stores the recipes (which contained the order in which the phases should be executed) but also stores all pertinent Parameter Values. With this modification, the operator is required simply to select a recipe together with all the equipment needed to run the batch. The batch engine is responsible for coordinating all the activities, including the parameter value transfer and Report information capture. The system also has the capability to prompt the operator regarding those tasks that require operator interaction. The installation of the addition did not interfere with any existing activities and all the existent code and functionality was preserved, with no changes being required.

Read More | Posted In: Case Studies, FactoryTalk Batch, Life Science Industry

Batch Forensics: Additional Report Parameters Enhance Process Performance

Understanding your process performance starts with having unambiguous data that is contextualized. This data provides information that quantifies and qualifies the different aspects that provide insight into the overall system performance. This data ends up in a repository and gets analyzed to produce actionable information and these reports may look at different aspects of the activities required to make products or to clean the equipment. By looking at the process from the ISA 88 and ISA95 point of view, we are able to provide additional context to the information for which the basic activities are reporting.

Understanding your process performance starts with having unambiguous data that is contextualized. This data provides information that quantifies and qualifies the different aspects that provide insight into the overall system performance. This data ends up in a repository and gets analyzed to produce actionable information and these reports may look at different aspects of the activities required to make products or to clean the equipment. By looking at the process from the ISA 88 and ISA95 point of view, we are able to provide additional context to the information for which the basic activities are reporting.

Additional information may be added to provide more insight into the activities related to:

- Quality – (amounts, tolerances, durations, temperatures, lethality, etc.)

- Cost- (materials, energy, personnel, equipment, etc.)

- Material information – (lot ID, material properties, storage locations, etc.)

- Personnel – (who is performing tasks, signoffs, etc.)

- Energy – (transport, heat/cool, mix, etc.)

- Equipment – (raw material source, equipment utilization, portable equipment information.)

– as well as other aspects that can be used to make informed decisions. (more…)

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Food Industry, Life Science Industry, Metals

Batch Forensics: The Case of the FactoryTalk Batch Timers

Frequently, we hear new and seasoned engineers say they do not use the Rockwell FactoryTalk Batch (FTBatch) Standard timers ($timer) because they cannot interact with them or can’t tell what the timer’s status is, as they do with controller-based timers. However, our Batch Forensic experts explain that this is not the case.

Standard Recipe timers require no design, implementation, testing, commissioning nor validation as required by timer Phases implemented in the controllers. Standard recipe $timers can be applied at all levels of the procedural model (Procedures, Unit Procedures, and Operations) Standard $timers can be used in as many placed as required, each instance of the timer is given a name defined by the recipe author that can be associated with the activity at hand. Timers are automatically added to the units configured on the area model just like the $Null Phase.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, FactoryTalk Batch, Food Industry, Life Science Industry

Batch Forensics by ECS Solutions

The term forensics refers to the application of scientific knowledge to problems, especially scientific analysis, and data analysis of physical evidence. In a plant environment, data and scientific analysis can be the key to discovering opportunities to improve the automation solution that exists, forensic tools can be implemented in all phases of the life cycle of a system, but ideally, they should be considered during the design phase.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry, Metals

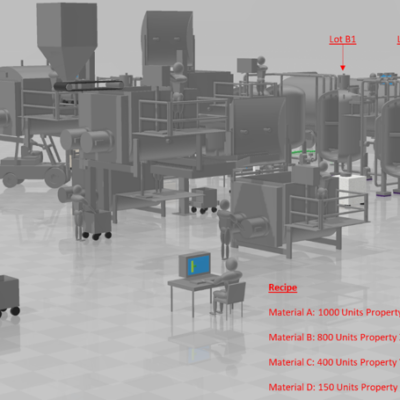

Dosing Materials Based On Their Properties

Improving Product Quality

Often the quantities of materials required to manufacture a product are specified by weight or by volume. Recipes and procedures are created to specify the activities that need to be performed and the number of materials required.

The Setpoints for these quantities are set in the recipes based on the materials that are being used, if the material properties change significantly then these recipe quantities need to be updated once the new materials enter the production stream. This often requires tracking the material consumptions and updating the recipes at the appropriate time. i.e. late at night on Saturday once the new material is introduced to the production environment.

These new formula quantities are calculated after a lab analysis is performed of each Lot sample. The timing to introduce these new recipe parameter values can be critical to the Quality and the Cost of the product.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers

Documenting Your Manufacturing Ecosystem

Understanding your manufacturing ecosystem is one thing, but documenting it is just as important. Having extensive documentation of the manufacturing ecosystem, helps those who aren’t involved in daily, plant-floor operations make informed decisions. Your manufacturing ecosystem is the system you use for making your product(s), and fully documenting and understanding this ecosystem will help the decision-making process of your organization.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry

Material Dosing Geneology

The Food industry uses batch manufacturing extensively and therefore requires traceability for material ingredients, i.e. the ability to follow the movement of a food product and its’ constituents all through the production process.

This capability not only largely prevents unsafe foods from reaching the consumer but also improves product quality and efficiency in the event of a recall.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers

The Benefits of Off-The-Shelf SOP Management Software

Being able to keep track of every step and every bit of data is a major necessity for every organization. An off-the-shelf standard operating procedure software is one way to implement new processes and keep track of business operating standards.

Tracking manual operations in discrete, batch, and continuous manufacturing processes can greatly benefit from off-the-shelf products. Clearly specifying your procedures, enforcing their execution, and capturing pertinent data are all major benefits that can be quickly and easily be obtained by implementing off-the-shelf, procedure management software.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry