News

Batch Forensics by ECS Solutions

The term forensics refers to the application of scientific knowledge to problems, especially scientific analysis, and data analysis of physical evidence. In a plant environment, data and scientific analysis can be the key to discovering opportunities to improve the automation solution that exists, forensic tools can be implemented in all phases of the life cycle of a system, but ideally, they should be considered during the design phase.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry, Metals

JTM Foods Case Study

JTM Foods challenged ECS Solutions and Blentech to create a SCADA system that included the full spectrum of process automation for their new state-of-the-art production facility. JTM wanted to expand their production capability with a new state-of-the-art facility featuring a Process Automated Kitchen. They wanted to track their process from the ERP Order through the procedural execution of the receipt and material tracking to a finished product. There were multiple solutions evaluated for each of the key aspects, via different islands of software. JTM operates efficiently with a very lean, experienced workforce, however, they prefer to minimize the requirements to support and sustain multiple technology platforms.

Read More | Posted In: Case Studies, Food Industry, SCADA

Manufacturing Digitalization That Works

Though digitalization is a process that is often seen as great, the benefits are not the same for everyone. Asking how digitalization is going to benefit your organization may be important to your digital future.

Industry 4.0, Industrial Internet of Things (IIoT), connected enterprise, and smart manufacturing, among others, are all descriptive of applying digital technologies to manufacturing. Often, digitalization is presented as so powerfully good that it just needs to be done, but most are generally skeptical, asking, “Exactly how is this going to help me perform better?”

Read More | Posted In: Blogs, Digitalization, IIoT

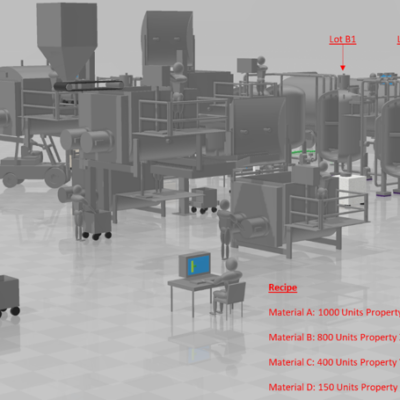

Dosing Materials Based On Their Properties

Improving Product Quality

Often the quantities of materials required to manufacture a product are specified by weight or by volume. Recipes and procedures are created to specify the activities that need to be performed and the number of materials required.

The Setpoints for these quantities are set in the recipes based on the materials that are being used, if the material properties change significantly then these recipe quantities need to be updated once the new materials enter the production stream. This often requires tracking the material consumptions and updating the recipes at the appropriate time. i.e. late at night on Saturday once the new material is introduced to the production environment.

These new formula quantities are calculated after a lab analysis is performed of each Lot sample. The timing to introduce these new recipe parameter values can be critical to the Quality and the Cost of the product.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers

Boosting Batch Performance at a Salad Dressing Plant

A well-known line of salad dressings was recently acquired by a major food manufacturer with the plan to establish a fully automated, paperless manufacturing process for the production. To do this efficiently and cost-effectively

represented a significant challenge.

Read More | Posted In: Case Studies, FactoryTalk Batch, Food Industry

Documenting Your Manufacturing Ecosystem

Understanding your manufacturing ecosystem is one thing, but documenting it is just as important. Having extensive documentation of the manufacturing ecosystem, helps those who aren’t involved in daily, plant-floor operations make informed decisions. Your manufacturing ecosystem is the system you use for making your product(s), and fully documenting and understanding this ecosystem will help the decision-making process of your organization.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry

Material Dosing Geneology

The Food industry uses batch manufacturing extensively and therefore requires traceability for material ingredients, i.e. the ability to follow the movement of a food product and its’ constituents all through the production process.

This capability not only largely prevents unsafe foods from reaching the consumer but also improves product quality and efficiency in the event of a recall.

Read More | Posted In: Bakery Industry, Batch Boosters, Beverage Industry, Chemical Industry, Distilleries, Food Industry, Life Science Industry, White Papers

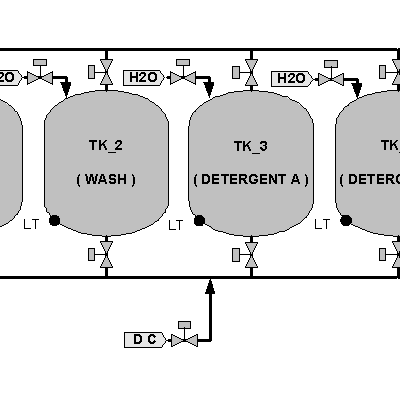

Large Consumer Goods Case Study

THE CHALLENGE

ECS was hired to upgrade and replace a CIP control system in one of the manufacturing areas for a large consumer goods company. The scope of work included a new control enclosure containing an upgrade from a SLC5 controller to a ControlLogix controller. The upgrade also consisted of all IO and connections within the enclosure. Additionally, the company wanted to solve the problem of inefficiencies in its CIP process by implementing FactoryTalk Batch and Batch control within this updated CIP system.

Read More | Posted In: Case Studies, Clean in Place, Consumer Goods

The Benefits of Off-The-Shelf SOP Management Software

Being able to keep track of every step and every bit of data is a major necessity for every organization. An off-the-shelf standard operating procedure software is one way to implement new processes and keep track of business operating standards.

Tracking manual operations in discrete, batch, and continuous manufacturing processes can greatly benefit from off-the-shelf products. Clearly specifying your procedures, enforcing their execution, and capturing pertinent data are all major benefits that can be quickly and easily be obtained by implementing off-the-shelf, procedure management software.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Life Science Industry

Flexible and Modular CIP and SIP Automation Enables Continuous Improvements

Clean In Place (CIP) and Steam in Place (SIP) constitute critical aspects of the bottom line of a manufacturing process, just as important as the products manufactured with the assets, CIP and SIP play a very important role in the product quality as well as the overall availability of the equipment to manufacture these products. Being able to consistently execute the required cleaning step regardless of the equipment level of automation is paramount, and being able to clearly specify and enforce the steps required are critical regardless of how these tasks are executed. Operators and equipment should seamlessly perform their task to ensure the desired cleaning procedures are executed in an optimum manner.

Read More | Posted In: Batch Boosters, Clean in Place, White Papers