News

DVR Module for Troubleshooting and Continuous Improvement

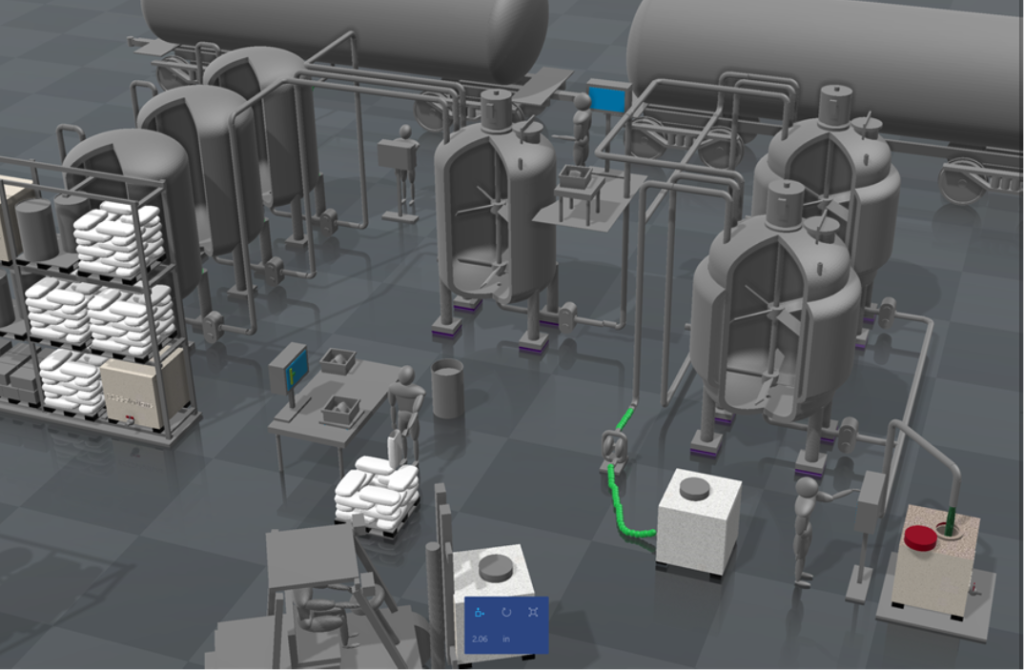

Effective mass production manufacturing operations involve both monitoring of production processes and continual improvement. ECS Solutions, Inc (ECS) has developed an innovative, powerful tool to help their clients develop peace of mind that their products are being manufactured accurately and efficiently while providing a platform to easily improve future interactions. The Process DVR tool satisfies the modern expectation that anything that can be observed visually should be recorded and easily viewed later. When used effectively, the result is truly optimized production control where the best-trained operators deliver accurate results with the least possible waste.

Data Historian capabilities have been built into many vendors’ SCADA systems for a long time. Astute process engineers can call up trending information that illustrates the states and conditions within an automated system, the multitude of lines crisscrossing an HMI terminal in a way their trained eyes can discern. This is an excellent tool by itself, provided that an operation has personnel who are trained to read and interpret the cryptic information that is returned from a standalone Historian. ECS believed that this was conceptually sound but that a more manageable solution would help to bring wider benefits to their processing clients.

Read More | Posted In: Bakery Industry, Beverage Industry, Chemical Industry, Clean in Place, Digitalization, Distilleries, Food Industry, Inductive Automation, Life Science Industry, SCADA

Batch Forensics: The Case for Procedural Unit Tags

A Unit Tag is a class-based tag that identifies a characteristic of a unit.

The values of these tags are usually associated with information captured via the control systems analog and digital Input cards, signals like Temperature, Weight, Pressure, Level, Conductivity, pH, Level Switch, etc. Other unit tags can contain the status, state, material of construction, or any other user-defined attribute that can enhance the recipe editing capability and execution.

Read More | Posted In: Bakery Industry, Beverage Industry, Distilleries, Food Industry

Large Consumer Goods Case Study

THE CHALLENGE

ECS was hired to upgrade and replace a CIP control system in one of the manufacturing areas for a large consumer goods company. The scope of work included a new control enclosure containing an upgrade from a SLC5 controller to a ControlLogix controller. The upgrade also consisted of all IO and connections within the enclosure. Additionally, the company wanted to solve the problem of inefficiencies in its CIP process by implementing FactoryTalk Batch and Batch control within this updated CIP system.

Read More | Posted In: Case Studies, Clean in Place, Consumer Goods