News

Innovative Tools for the Evolving Systems Integrator

The personnel challenges facing virtually every industry over the last few years have been nothing short of astonishing. Proper candidates have become increasingly difficult to court and bring on board. New staff in key roles are tasked to accomplish more with fewer floor operators and technology is increasingly leveraged to close the resulting gaps. This is not unique in history although it may seem that way due to the current media deluge surrounding business intelligence and general-purpose visibility software that makes life easier, smarter, and generally more efficient.

Industrial software is again playing a leading role in the current intelligence revolution. Inductive Automation didn’t invent floor supervisory (SCADA) software, nor did they invent the first responsive, general-purpose web software. However, their current offerings certainly do marry these concepts together in a way that hasn’t existed in industry before. Since 2010 their award-winning Vision Module has enhanced the experiences of factory floor users everywhere, easily connecting complex factory controllers to databases, alarm and reporting systems, and intuitive visualization tools. This product is robust, proven, and works very well for users “inside the industrial network” of many facilities. Today this is coupled with the newer Perspective Module which is an equally powerful tool for use in mobile-responsive applications. For situations where a user may be “outside the industrial network” or simply need to utilize a variety of hardware platforms like PCs, phones, or tablets, Perspective provides an ideal solution.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Consumer Goods, Food Industry, Inductive Automation, Life Science Industry, Metals Industry, SCADA

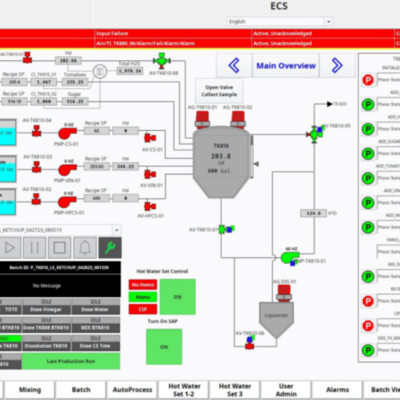

ECS & Ignition Deliver for AmeriQual

Success in many industries is the product of preparation and opportunity. Agility is frequently the lubricant that enables businesses to adapt and win a project or contract. This is especially true in private-label food manufacturing. “The people, processes, and equipment must be able to adapt to ever-changing market demands,” says Wes Blankenberger, Vice President of Operations & Maintenance for AmeriQual Group, LLC, in Evansville, IN (AmeriQual). Brand owners must beat their competition to market and the best way to do that is frequently via a capable private labeling partner. Much like brand owners leverage private label manufacturers, the manufacturing plants themselves leverage partners to assemble existing and new equipment into functional processing systems, often on aggressive timelines.

Similar traits and situations define success inside of the control system integration space. Much like private label manufacturing, clients call upon these firms because of their known ability to deliver in specialized market segments. They’re well-trained and typically gainfully employed by clients where they excel. Rarely are they entirely idle but their mix of professionals at different levels and specialties allows them to apply staff, often on short notice, to applications. Their highly trained teams can tackle projects or parts of projects large and small, often in concert with their teammates or outside firms.

Read More | Posted In: Case Studies, Chemical Industry, Uncategorized

Using Ignition Scripting Libraries

Volumes have been written about the proper use of tools within a software application and how to create projects for maximum efficiency in both development and execution. Senior programmers and leaders of development teams strive to write and deploy robust solutions that are simple, efficient, easy to debug, and easy to adapt in the future.

Ignition is a multi-faceted tool that continues to revolutionize industrial applications. The package includes a powerful scripting tool that has undergone significant upgrades from versions 7 and before and has existed in its current form since version 8. When combined with the software’s other capabilities and using a disciplined approach to the application of all the tools, Ignition can give you efficient and optimized solutions that can solve most SCADA and business integration challenges.

Read More | Posted In: Blogs, Inductive Automation

Ignition Perspective® Module

Human-machine interface (HMI) vendors have been promising a utopia based around web-based technologies for over two decades. The prospect of simply providing a web address to anyone within an organization that leads to a fast-loading, full-power supervisory control and data acquisition (SCADA) system has been on most factories’ wish list for a long time. After all, internet page tools and functionality have far outpaced advancements in SCADA software over the same time. The advancements seem to leap forward every time someone reloads a page, with new widgets and tools available almost daily. When coupled with hardware developments like high contrast screens; enhanced touchscreen operations; and capabilities like Bluetooth, accelerometers, geolocation, and more; a flexible, web-based option has been coveted.

What many casual users fail to understand about HMI solutions is exactly how tightly the software is connected to the factory floor controllers. This connection via high-security networks, VPNs, and masks, can be tricky to navigate, particularly when the architecture is intentionally complex to provide security for the systems. Further, most people don’t realize the architectural complexity of software that link to sometimes multiple databases and remote data sources, where gigabits of proprietary information streams into and out of the SCADA application. It has been the responsibility of the integrators of these solutions to protect would-be users from themselves in a lot of applications. Poorly developed programs could create vulnerabilities to the operation of equipment, expose floor workers to potential risk, and possibly allow trade secrets to escape into cyberspace.

Read More | Posted In: Bakery Industry, Beverage Industry, Blogs, Chemical Industry, Distilleries, Food Industry, Inductive Automation, Metals Industry, SCADA

Case Study: Integrating PlantPAx into an Existing Process Cell for a Pharmaceutical Company

A major pharmaceutical company was in the process of commissioning a control system for a new process cell and asked ECS to provide site support to complete the commissioning and qualification.

The control system supplier had taken a simplistic approach to keep costs down. A single controller with multiple Panelviews provided the heart of the control system that also interfaced with some OEM skids. The control hardware consisted of a quality Rockwell ControlLogix controller with multiple Panelviews. The controller code was all custom with little use of off-the-shelf products and was an assortment of custom blocks of code tied together, providing minimal functionality.

Little to no thought had been put into the operator and how they would run the system to create quality product. Standard operating procedures had not yet been developed. Producing a quality product was dependent upon the operator selecting the correct sequence of functions from operator stations at multiple vessels. This approach exposed the company to a great deal of risk in producing a quality product and controlling the rate of production.

Read More | Posted In: Case Studies, FactoryTalk Batch

Case Study: An Expansion of a Water Treatment Plant

A municipal utility asked ECS Solutions to design and construct an expansion to one of their Water Treatment Plants. It was proposed to expand an existing facility from ten million gallons per day (MGD) to a total treatment capacity of 30 MGD and upon completion of the expansion, an existing 18 MGD plant was to be shut down.

Earlier, ECS had provided the configuration and start-up support for the SCADA system used to operate the plant and had installed the existing SCADA and control system at both the plant to be expanded, and the one ultimately to be shut down. The proposal provided by ECS Solutions for the expansion covered the control and/or monitoring of:

- Four existing and four new aerators.

- Existing and new primary and secondary settling basins.

- Existing sludge and reclaim equipment.

- All existing and eight new filters.

- Existing and new high service pumps.

- New chemical feed equipment for lime, sodium hypochlorite, fluoride, and polyphosphate.

Read More | Posted In: Case Studies, SCADA

Case Study: Ignition at Large Food Manufacturer

A large food manufacturer requested assistance from ECS Solutions in replacing a SCADA/HMI system that was unreliable and difficult to maintain. After consultation with us, they selected the Ignition platform from Inductive Automation. Ignition provides a reliable platform that can be supported and developed internally or by system integrators. Ignition would provide the power to reliably replace the existing system and the flexibility to extend the application to other functional areas of the plant, allowing visibility across the plant from a single system. Additionally, Ignition allowed one common platform to be used to control the processing and the packaging areas of the plant.

Read More | Posted In: Case Studies, Food Industry

5 Reasons Why Ignition is the Future of the Food & Beverage Industry

*Thank you to Inductive Automation for including us in this important piece!

In today’s world, automation is a necessity for all manufacturers. Food and beverage manufacturers in particular face a variety of challenges that make an investment in automation and supervisory control essential to remaining competitive. The market changes abruptly and often: recipes need to be reformulated to accommodate diet trends, the constant demand for innovative packaging to attract new customers, and seasonal variance of production requirements are all factors that must be considered.

Beyond FDA and FSMA regulations, manufacturers must also take into account classification and segregation of allergens during formulation and equipment cleaning, a process that mirrors requirements in the pharmaceutical industry. “The way we’ve been doing things for a long time is based on our pharmaceutical experience and seeing how food and pharmaceutical are kind of like coming closer and closer. In terms of the automation solution, it will look the same to us. It doesn’t matter if it’s food or if it’s medicine,” said John Parraga of ECS Solutions. Simply put, insufficient interoperability can endanger both public health and an organization’s bottom line.

Read More | Posted In: Inductive Automation

Case Study: An Upgrade to Ignition Sepasoft “Perspective” OEE & Downtime Module

A global consumer goods manufacturer hired ECS Solutions to evaluate and install an upgrade of an Ignition Application from Version 7.9 to Version 8.1. Version 7.9 was originally installed by ECS Solutions. The overall objective for the company was to have a web-based client application that was independent of Java and based on HTML5. The upgrade included a reconfiguration of the MES software to improve its effectiveness.

The previous Ignition “Vision”-based Application did provide the functionality to monitor Equipment Downtime and Overall Equipment Effectiveness (OEE), but the use of Java within the Ignition modules conflicted with other applications at the site and made it difficult to access throughout the organization. Migration to the web-based Perspective Platform allowed ECS to significantly lighten the application and to focus on the most important data. The new version of the Sepasoft OEE module also made it possible to simplify how the workstream was modeled within the Sepasoft Production module. The company required this application be designed to work with both PCs and iPads.

Read More | Posted In: Consumer Goods

Strong Collaboration & Swift Implementation (Episodio en Español)

El presidente de ECS Solutions, Tim Matheny junto con Brad Logsdon, analista de negocios de Swedish Match se juntaron con Travis Cox el Codirector de ventas de ingeniería de Inductive Automation para una entrevista acerca del proceso de la implementación de Ignition para el análisis de sus negocios.

En este video, John Parraga nos resume en Español el contenido de esa reunión que explica como Swedish Match de Norte América llegó a utilizar la plataforma de Ignition para resolver problemas de negocios reales, y como el departamento de informática lideró la inversión inicial en su facilidad de Owensboro Kentucky.

Read More | Posted In: Inductive Automation